1. Product description

Name:High Quality DH360 Bucket Teeth Bucket Excavator Tooth 2713-00032

Techniques:100% Hot-die Forging Bucket Teeth

Color: Yellow, Gree or Specify Colors

Hardness:48-52 HRC

Packing:Standard wooden case or custom make as per required.

How to purchase: Just send us your inquiry list from online service or by mail or SKYPE, we will quote best price to you immediately.

2. More photo of Bucket Teeth:

3. WSG Advantages:

XIAMEN WINSUM (WSG) MACHINERY CO., LTD

is one of the leading and professional suppliers of Our products are high quality at good prices, certified by ISO9001:2000, specifically designed, engineered and manufactured under consistent quality control. We also make according to OEM requirements. Especially, we can produce new products according to your samples, designs or technical drawings.We have exported all over the country such as South America, Europe, the Middle East, Africa and so on. Our products are recognized and accepted for high quality, we are enhancing the market share.

Advantages:

1. Quality guarantee and control

2. Technical support

3. Producing according to drawing

4. Gather different parts into one container

5. LCL is acceptable

6. Utilize TNT, UPS, DHL for urgently order

7. Customized part labels is acceptable

8. Delivery Merchandise in time

9. Unobstructed communion

With the principle of "Good quality, best services, reasonable prices", we sincerely look forward to establishing stable, long-term and strategically cooperative partnerships with old and new customers from all over the world for our bright future, mutual cooperation. Let us promote each other and create a new and happy tomorrow hand in hand.

Welcome to contact us to know more! We believe we will be your best partner and choice.

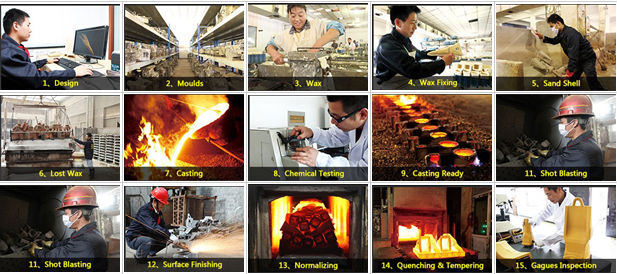

4. WSG The production process of bucket teeth

|

Chemical Composition & Mechanical Properties |

|||||||

|

No |

Material No |

Product |

Impact Toughness (ak/JC m2) |

Hardness HRC |

Tensile Strength |

Elongation |

Working Condition |

|

1 |

1# |

Adapter,side cutter, protect panel etc. |

>= 15 |

40~46 |

>= 1300 |

>= 4 |

Normal temperature |

|

2 |

2# |

Teeth/Loader teeth |

>= 13 |

48~52 |

>= 1500 |

>= 4 |

|

|

3 |

3# |

Adapter(>40tons machine) High Quality |

>= 20 |

40~46 |

>= 1350 |

>= 5 |

|

|

4 |

5# |

Teeth (>20 tons machine) high quality |

15~25 |

50-54 |

>=1550 |

>= 5 |

|

1.WAX INJECTION: JCB bucket teeth Wax design of the desired castings are produced by injection molding.These designs are called patterns.

2.ASSEMBLY: The patterns are attached to a central wax stick,called a sprue,to form a casting cluster or assembly.

3.SHELL BUILDING: The shell is built by immersing the assembly in a liquid ceramic slurry and then into a bed of extremely fine sand.Up to eight layers may be applied in this manner.

4.DEMAX: Once the ceramic is dry,the wax is melted out,creating a negative impression of the assembly within the shell.

5.CONVENTIONAL CASTING: In the conventional process,the shell is filled with molten metal by gravity pouring.As the metal cools, the parts and gates,spure and pouring cup become one solid casting.

6.KNOCKOUT: When the metal has cooled and solidified,the ceramic shell is broken off by vibration or knock-out machine.

7.CUT OFF: The parts are cut away from the central spure using a high speed friction saw.

8.CLEANING AND GRINDING: When the fomred casting parts are finished, they will be cleaned by hand work totally.After that, all the parts will be put in to the grinding machine for spot blasting. After these operations, the metal castings becomes identical to the original wax patterns.

9.HEATTREATMENT: Once the parts for Jcb bucket teeth are finished by cleaning, they will be put in to heattreatment machine , in order to get a good harness and anti-wearness,as well as good impact performance.

10.PAINTING: Sprat painting method is used to paint the parts with different colors. Then they will be given special time for dry, so that they can be kept as shining and smooth.

11.PACKAGE: Man-made wooden carton is used for package,which is no need for fumigation.

12.SHIPPMENT: When all these work is done, finished products for Jcb bucket teeth is ready to ship to every cornor of the world.

6.Authority certification

7. There are more model for bucket tooth as follow for you reference:

|

Model | Part Number | Model | Part Number | Model | Part Number | Model | |

|---|---|---|---|---|---|---|---|---|

| 20X-70-14160 | PC60 | 6I6602 | J600 | 8J2936 | SK230LR | 230 SIDE CUTTER | ||

| 20X-70-23161 | PC100 | 4T4702 | J700 | 5K8959 | 18S | For HITACHI55 | ||

| 202-70-12130 | PC120 | 8802 | 6Y0649 | J350 | 22S | For HITACHI70 | ||

| 205-70-19570B | PC200 | 1U3302SYL | J300 | 1U1858 1U1859 | 25S | PC60 | ||

| F01A205-70-19570C | 1U3352SYL | J350 | 1U1878 1U1879 | 30S | PC100 | |||

| 205-70-19570HD | 7T3402SYL | J400 | 1U1888 1U1889 | J350 | 35S | PC200 | ||

| 207-70-14151-1 | PC300 | 9W8452SYL | J460 | 6200064 | 40S | PC300 For HITACHI240 | ||

| 207-70-14151-201 | 9W8459 | J460 | 9F5124 | 45S | ||||

| 207-70-14151HD | PC200 | 9W8559 | J550 | 9J6586 | 25R12 | |||

| 208-70-14152 | PC400 | 9N4252 | J250 | 6Y5230/2D5572 | 25R15 | |||

| 208-70-14152HD | 9N4302 | J300 | 4J8665 | 27 | ||||

| 208-70-14270 | 9N4352 | J350 | 4T6695 | 35 | ||||

| 209-70-54210 | PC600、650、800 | 8E4402 | J400 | 4T6699 | 35T | |||

| 21N-70-14290 | PC1000 PC1250 | 9N4452 | J460 | 116-7460 | 230SP | |||

| 205-70-19570RC | PC200 | 9N4552 | J550 | 116-7461 | 230ST | |||

| 205-70-19570RC-2 | 9J4309 | J300 | 116-7462 | X156 | ||||

| 205-70-19570RC-3 | 9N4303 | 114-0464 | X160 | |||||

| 207-70-14151RC | PC300 | 4T2353 | J350 | 114-0465 | X290 | |||

| 207-70-14151RC-1 | PC300 | 9N4253 | J250 | 114-0466 | X400 | |||

| 208-70-14152RC | PC400 | 9N4353 | J350 | 8E7300 | X370 | |||

| 208-70-14270RC | 9W1453 | J450 | 855-25 | X310 | ||||

| 209-70-54210RC | PC600、650、800 | 9N4453 | J460 | 6Y0309 | D4 955 | X410 | ||

| 208-70-14152TL | PC400 | 6Y2553 | J550 | 6Y0359 | D5 D6 D7 | X500 | ||

| 207-70-14151TL | PC300 | 4T4703 | J700 | 9W2451 | D7 D8 | 156-50 | ||

| 209-70-19570 | PC200 | 4T2303RP | J300 | 9W2452 | D8 D9 D8K | X156FL | ||

| 207-70-14151 | PC300 | 9W1453RP | J460 | 4T4501 | R500 | X156XFL | ||

| 208-70-14152 | PC400 | 1U3302P | J300 | 4T4502 | R500 | 940X370 | ||

| 423-847-1140 | WA500 | 1U3352P | J350 | 4T5501 | D8K D9 D8L | 940X400 | ||

| 426-847-1110 | WA500 WA600 | 7T3402P | J400 | 4T5502 | D8K D9 D8L | 14527863 | 140 | |

| 20X-70-14151(PC60) | PC60 | 9W8452P | J460 | E315 | E315 SIDE CUTTER | 11530544 | 210 | |

| 20X-70-12140(B100) | PC100 | 9W8552P | J550 | 096-4747-4748 | E320B SIDE CUTTER | 1171-00041 | 240 | |

| 20X-70-14151(B100) | 1U3302TL/9W8309 | J300 | 2322147 2322148 | SIDE CUTTER | 1171-01910 | 290 | ||

| 202-70-12140 | PC120 | 7T3402TL | J400 | 7Y0359 7Y0358 | E330 SIDE CUTTER | T55GP | 360 | |

| 205-939-7120-F02 | PC200 | 9W8452TL/7T8459 | J460 | 112-2489 | SIDE CUTTER | E460 | 460 | |

| 205-939-7120(3CM) | 9W8552TL/9W6559 | J550 | GET-1 | VO360RC | 360 | |||

| 205-939-7120(3.5CM) | 6I6602TL/107-8609 | J600 | GET-2 | VO460RC | 460 | |||

| 205-939-7120(4.0CM) | 1U3202WTL/135-8208 | J200 | 220-9089(M-1) | TOOTH | 1171-01620 | 210 | ||

| 205-939-7120(4.5CM) | 1U3252WTL/135-8258 | J250 | 8J2936 | TOOTH | 1171-01900 | 290 | ||

| 205-939-7120(2211) | 1U3302WTL/135-9308 | J300 | 220-9089 | TOOTH | VO360 5.2 | 360 | ||

| 939-5120(B300 3.5CM) | PC300 | 1U3352WTL | J350 | 220-9093 | TOOTH | V0360 6.2 | 360 | |

| 939-5120(B300 4.0CM) | 7T3402WTL | J400 | 18S | DH55 | E460 5.5 | 460 | ||

| 939-5120(4.0CM) | 1U3252RC | J250 | 2713Y1221 | 130 | E460 6.2 | 460 | ||

| 939-5120(4.5CM) | PC300 | 1U3302RC | J300 | 2713Y1217 | 220 | 1171-00171 | 210 SIDE CUTTER | |

| 939-5120(5.0CM) | 1U3352RC | J350 | DH220(2713-9041) | 220 | H290 LR | 290 SIDE CUTTER | ||

| 939-5120(5.5CM) | 7T3402RC | J400 | 2713Y1219 | 280 | VO460 | 460 SIDE CUTTER | ||

| 208-939-3120(4.5CM) | PC400 PC450 | 7T3452RC | J450 | DH280(2713-9038) | 280 | 19587B | THREE BOLT BOARD | |

| 208-939-3120(5.0CM) |